MORE Technologies last week launched a Kickstarter campaign to raise US$20,000 for development of its open source robot ecosystem.

The company will fund the project if it reaches its goal by April 21. As of this writing, $6,485 of that $20,000 goal has been pledged.

It teaches real tech skills to the next generation of innovators and problem solvers using MOREbot — a series of open source, customizable robotics kits designed for classroom or home use.

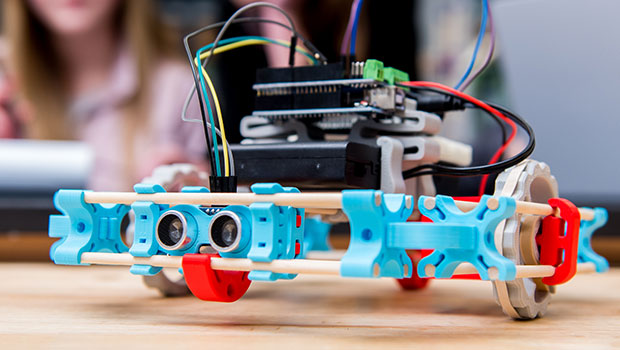

MOREbot is an expandable modular STEM (Science, Technology, Engineering and Math) learning robotic ecosystem. All robot parts are 3D printed, which makes it very affordable, according to the company.

Combining open source and 3D printing technology positions MORE Technologies well for sustaining its innovative approach to learning about robot culture, observed Daniel Codd, a professor at the University of San Diego’s Shiley-Marcos School of Engineering.

“Open source platforms have proven useful to make technologies more accessible — at times leveraging community user development for rapid innovation cycles,” he told LinuxInsider. “Similarly, 3D printing has benefited from open source development, enabling lower cost devices and a wider user base.”

If its fundraising efforts are successful, MOREbot’s hands-on approach to joining two well-known open source technologies will help educate a new generation of roboticists, said Codd.

However, the open source connection might make it difficult for the company to realize recurring revenues from product sales, he cautioned.

“Establishing MOREbot as a STEM/maker/robotics community network may be the best path for longevity,” Codd suggested.

What It Does

MOREbot’s developers designed its robot ecosystem to grow with users as they learn. The base robot is easy for beginners starting at age eight. Beyond that, the system grows with the user’s skills, so it becomes a powerful tool — even for an expert.

The ecosystem includes modular components, 3D printed parts, open source learning and Bluetooth-controlled apps. MOREbot teaches valuable tech skills, like coding, 3D printing and electronics, using the Arduino platform. It also prepares users to become makers, while teaching skills like problem-solving and design thinking that can help them adapt to a fast-changing world.

Arduino is an open source electronics platform based on easy-to-use hardware and software to operate interactive projects. Arduino boards can read inputs — such as light on a sensor or a finger on a button — and turn them into outputs, such as activating a motor or turning on an LED.

Market Support Possible

The open source nature of the MOREbot project could be its most marketable trait. That has been the experience of the Fab Foundation.

“A large number of projects in our 1,600 fab labs around the world are open sourced and highly successful,” noted Sarah Boisvert, founder of Fab Lab Hub and author of The New Collar Workforce.

Examples include Local Motors’ innovative Crowdsourced Rally Car, an appliance program with GE, and Olli, a 3D-printed self-driving short-range shuttle, she said.

“Scalability will be the challenge for MOREbot,” Boisvert told LinuxInsider.

Open source projects are not always sustainable, said Jory Denny, assistant professor of computer science in the University of Richmond’s Department of Mathematics and Computer Science.

“I am not confident their model is sustainable, but the technology landscape is constantly changing, and they might just pull it off,” he told LinuxInsider. “They certainly have the excitement and motivation to do so.”

Basic Skills

MOREbot learning starts with building a Base Robot and then controlling it via a mobile app. Add-on kits expand the learning curve and the functional capability of the robots.

Each kit can function alone. Users create simple structures and work up to building more complex and sophisticated robots.

The Game Kit transforms the MOREbot into an interactive device with a screen and multiple controls. The goal is to engage users in learning the base concepts of games programming.

The kit is used in 15 lessons with varying levels of difficulty. Users can remix modules for experiments in every lesson. The endgame is to build, wire and program the MOREbot platform into a full controller and game system.

Expansion Kit Strategy

The Catapult Expansion gives the MOREbot creation the ability to launch small projectiles using a mobile phone as a control launcher. It is easily added on top of the base robot. Changing the rubber band configuration changes the power of the catapult. The catapult is useful for teaching physics concepts such as force, torque and springs.

The Robot Arm Expansion adds a hand or claw. Snap the Three Degrees of Freedom (DoF) arm on top of the MOREbot base to enable the robot to pick up objects. Each joint uses a 20Kg/cm digital servo, and each arm section is six inches long. The servo mounts interface with the MORE ecosystem.

The Structure Kit uses the MOREbot ecosystem to create more complex projects. It comes with the core 3D printed parts and plenty of wooden dowels.

The Motion Kit is the most advanced add-on component, as it provides the ability to give advanced mobility to MOREbot creations. It includes gears, servos and motors.

The Sensor Kit brings the element of perception to MOREbot’s world. This kit teaches how to wire, code and use each sensor with an applied lesson.

Combine the Structure kit with the Sensors and the Motion kits to get the most out of the MORE ecosystem.

MOREbot Marketplace

The company offers printable 3D files for MOREbot parts on the Makerplace section of its website. This is a subscription-based online learning platform. Also available through Makerplace are tutorials, part files, and example projects for everything in the MOREbot ecosystem.

“I think there is a niche market for this product. However, there are many cheap and lightweight robot kits out there. Some have been extremely popular — for example, Lego MindStorms,” said Denny. “So if they can find the right aspect to market, they can be successful.”

Open source projects like this sometimes can gain real steam and provide great services to many people, especially otherwise-disadvantaged groups. he noted.

Robotics and 3D Printing Key

Robotics is a key technology for the digital transformation of business and a rapidly growing industry, according to Boisvert.

New tools like robotics will be adopted only if there are trained operators, technicians, engineers and scientists to design, program, run and service the machines, her research for The New Collar Workforce showed.

“3D Printing has come a long way with the introduction a few years ago of the HP production 3D Printer. With big players like HP and Trumpf laser entering the market, speeds and quality have improved,” Boisvert said.

3D printing is the perfect niche for small businesses like MOREbot because its parts are simplistic and easy to replicate, said University of Richmond’s Denny.

“In the long run, they would need a different model for mass production if their product really takes off,” he said. “As for robotics, many small robots are being 3D printed.”

The advantage with 3D printing is that the process allows for robots to be designed, prototyped and tested for a specific task easily, efficiently and cheaply, Denny explained. The MOREbot kit seems simple and complete to teach the basics of building robotics, simple electronics and computer programming.

“It appears their emphasis will be on the latter part,” he said.

Practicality Counts

The two most practical aspects of MOREbot are its potential to broaden participation in STEM, and to educate engineering and computer science participants, Denny said.

A kit like the MOREbot model can be integrated into educational programs for young children before they might develop a mindset that they cannot succeed as an engineer, he suggested. “Innovations like this are beginning to close the gender and race gaps present in engineering.”

A simple kit for early education of engineering projects can augment learning for any child, Denny added. It can expose students to fields they might not have considered before, and really instill a passion for lifelong learning.